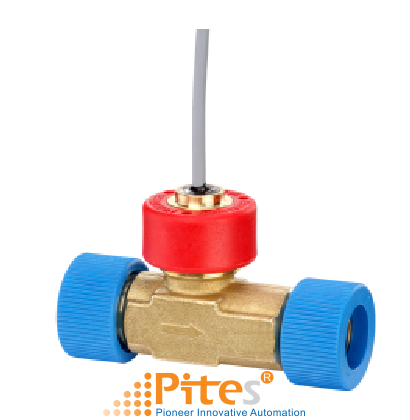

Turbine flow sensor

Xuất sứ: Germany

Nhà cung cấp: Pitesco Vietnam

Possible areas of application

The VTM 15 MS-31 are sensors for liquid flow measurement in solar heating plants. With compact dimensions and high measurement accuracy, they offer, compared to conventional water meters, convincing advantages:

- A temperature sensor can be integrated into the turbine body saving additional installation costs

- The maximum medium temperature of 120 °C offers sufficient safety and reliability for all operating conditions.

Description

Measuring principle

The liquid flowing into the turbine flow sensor is split into individual jets by the guiding blade. These jets hit the rotor evenly from different directions, setting the rotor in motion. The rotation speed of the rotor is then converted to an electrical pulse signal (frequency): The rotors are fitted with magnets and a Hall effect sensor detects the rotation of the rotor. The VTI series has stainless steel pins in the rotor. An inductive proximity switch detects the rotor rotation. In both cases, a flow-proportional frequency signal (square-wave signal) is made available.

Given the uniform inflow to the bearing, the forces largely cancel themselves out and wear is reduced to a minimum. The extremely hard bearing materials - sapphire and tungsten carbide - also guarantee an exceptionally long endurance.